CHIKOUSA ZAM TOUGH

ZAM (Zinc + Aluminum + Magnesium)

Coated Steel for Corrosive Environments

CHIKOUSA now offers ZAM TOUGH coated steel on all Solar Carports and Gazebos. ZAM is a technologically advanced coated steel that provides superior benefits in corrosive environments. ZAM is the next generation of hot-dip coated steel products. ZAM is a hot dip coating for steel comprised of Zinc-Aluminum-Magnesium, (ZAM), which provides far greater corrosive resistance than galvanizing alone. This advanced corrosive resistance is highly beneficial in extreme climates such as high chloride and ammonia, like those used to house livestock and agricultural environments. Also our ZAM Tough application provides superior corrosion resistance within high salt coastal environments.

The ZAM coating is a blend of zinc, aluminum and magnesium. The magnesium and aluminum combine to form a protective barrier on the surface of the coating. This strongly attached barrier creates a two-layer structure on the surface of the steel that suppresses corrosion of the coating layer and enhances the corrosion resistance of the product. Resulting in a corrosive resistance that is at least 3 times that of standard galvanized steel.

Key Benefits of ZAM on our Solar Carports and Gazebos

Salt Environments

Agricultural Environments

Potential Installation Sites

Farming and Agriculture

Coastal Environments

Marinas and Boat Sheds

Refineries & Industrial Environments

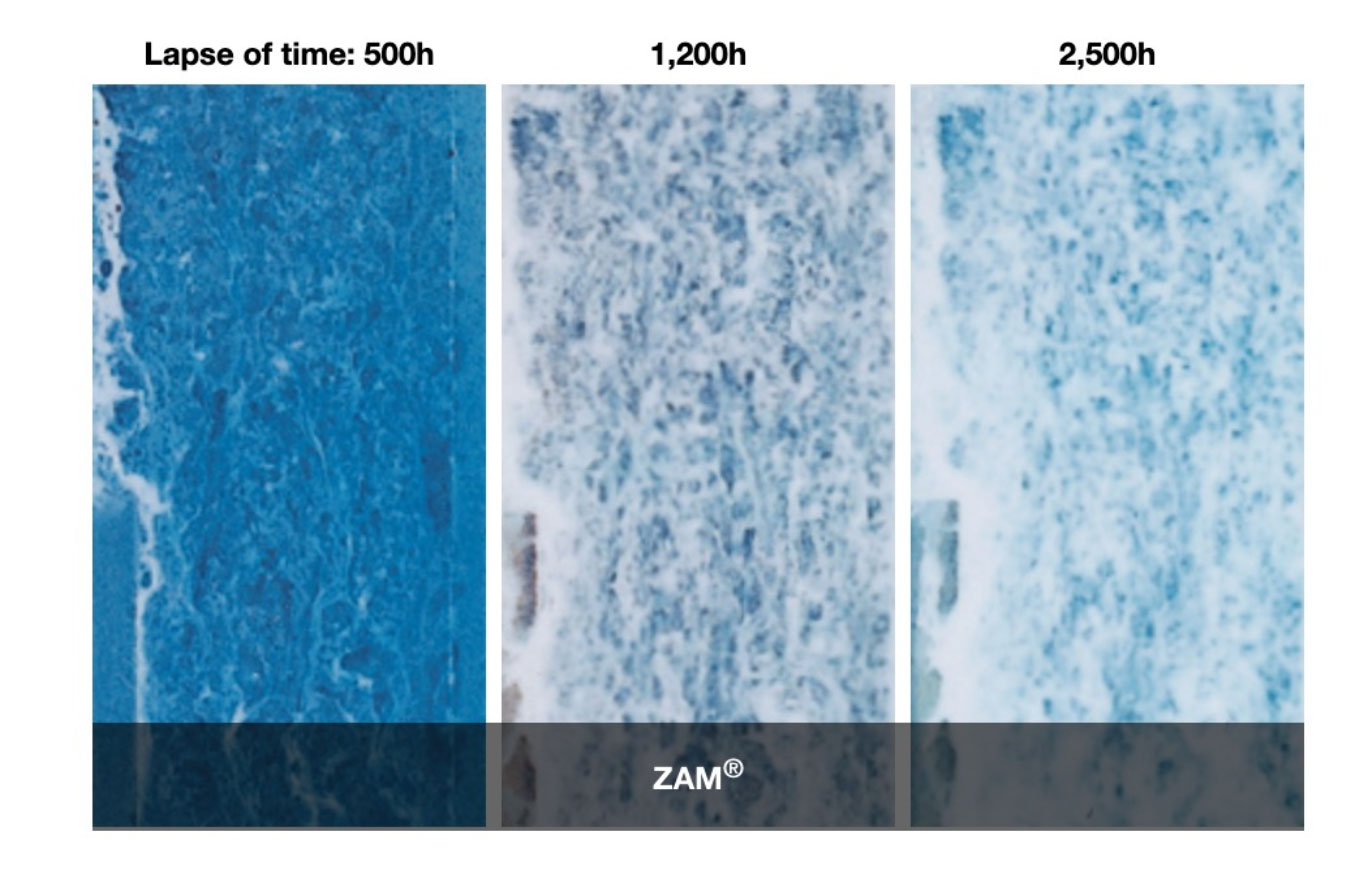

Getting a CHIOUSA Solar Carport or Gazebo with our ZAM Tough coating will provide you

with advanced corrosion resistance that our competitors Galvanized solution cannot.

CHIKOUSA ZAM Tough

vs.

CHIKOUSA ZAM Tough

Competitor's Steel

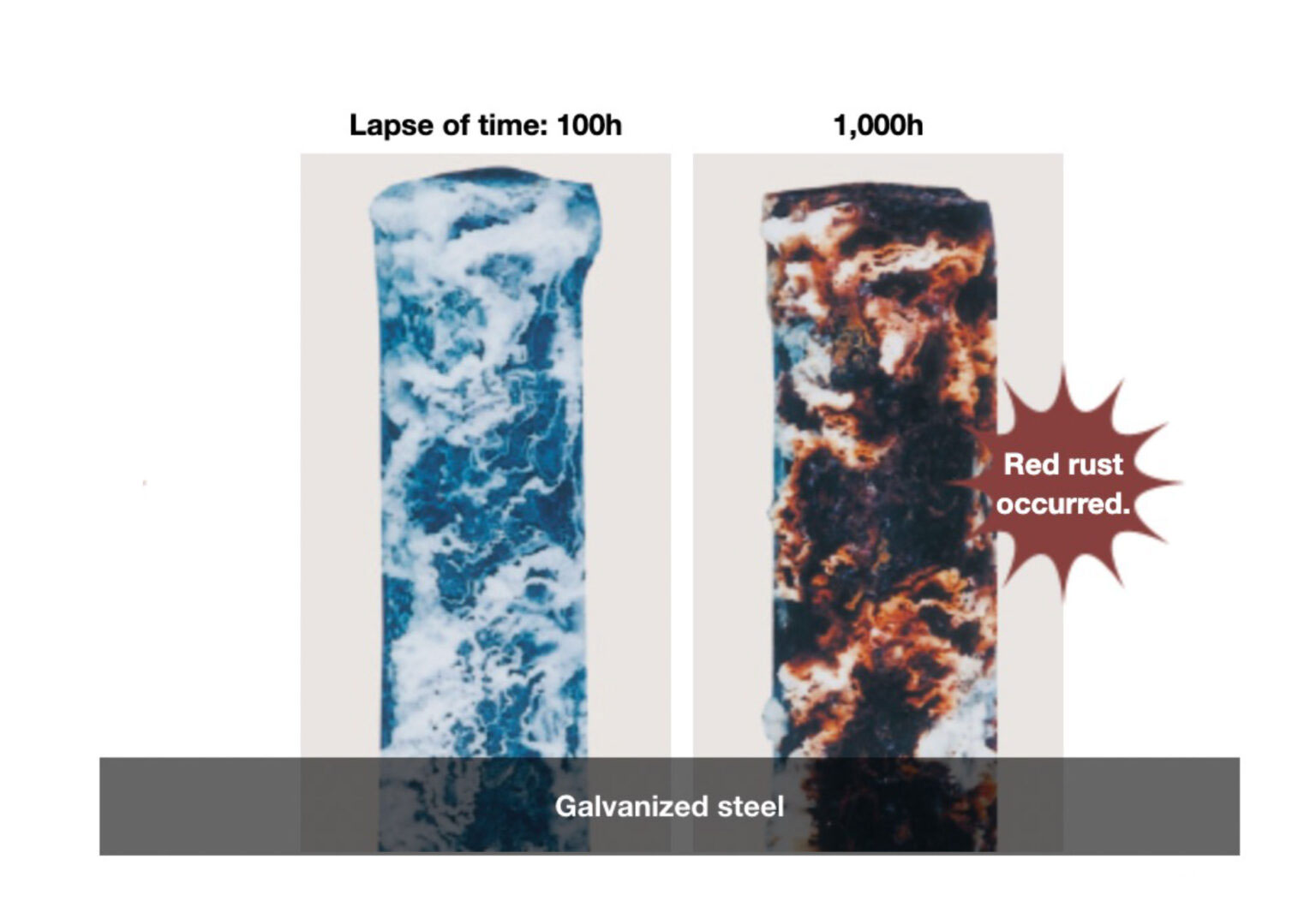

Results of salt spray test (SST: JIS Z 2371) Appearances of specimens after salt spray test.

(Coating weight: 90/90 g/m, untreated)

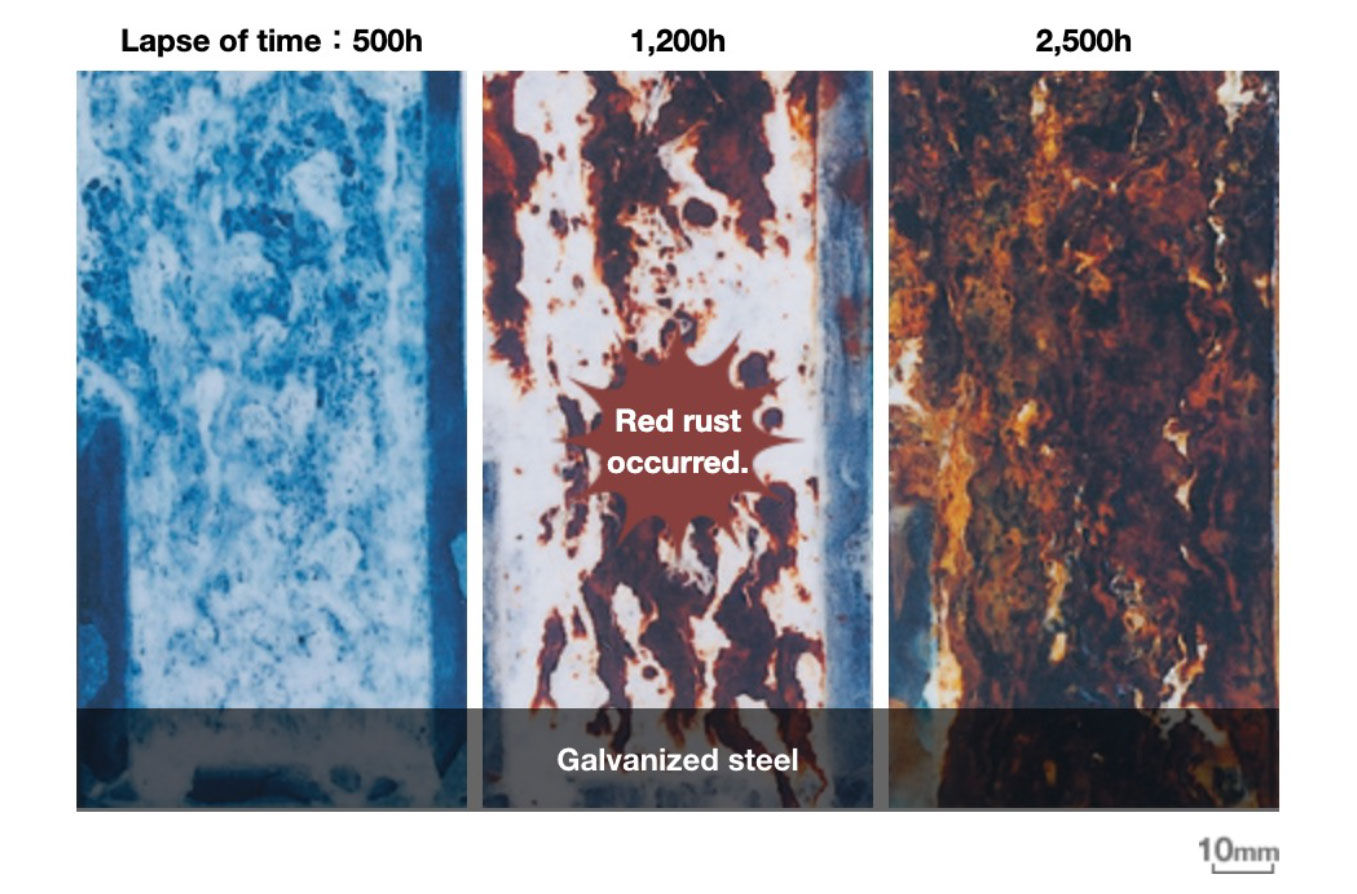

Corrosion Resistance Of Bent Sections

ZAM shows better corrosion (red-rust) resistance even in bent sections

vs.

CHIKOUSA ZAM Tough

Competitor's Steel

Appearances of 1t bent section after salt spray test

(1t, 180 bending, thickness: 3.2mm, 120/120 g/m, untreated)

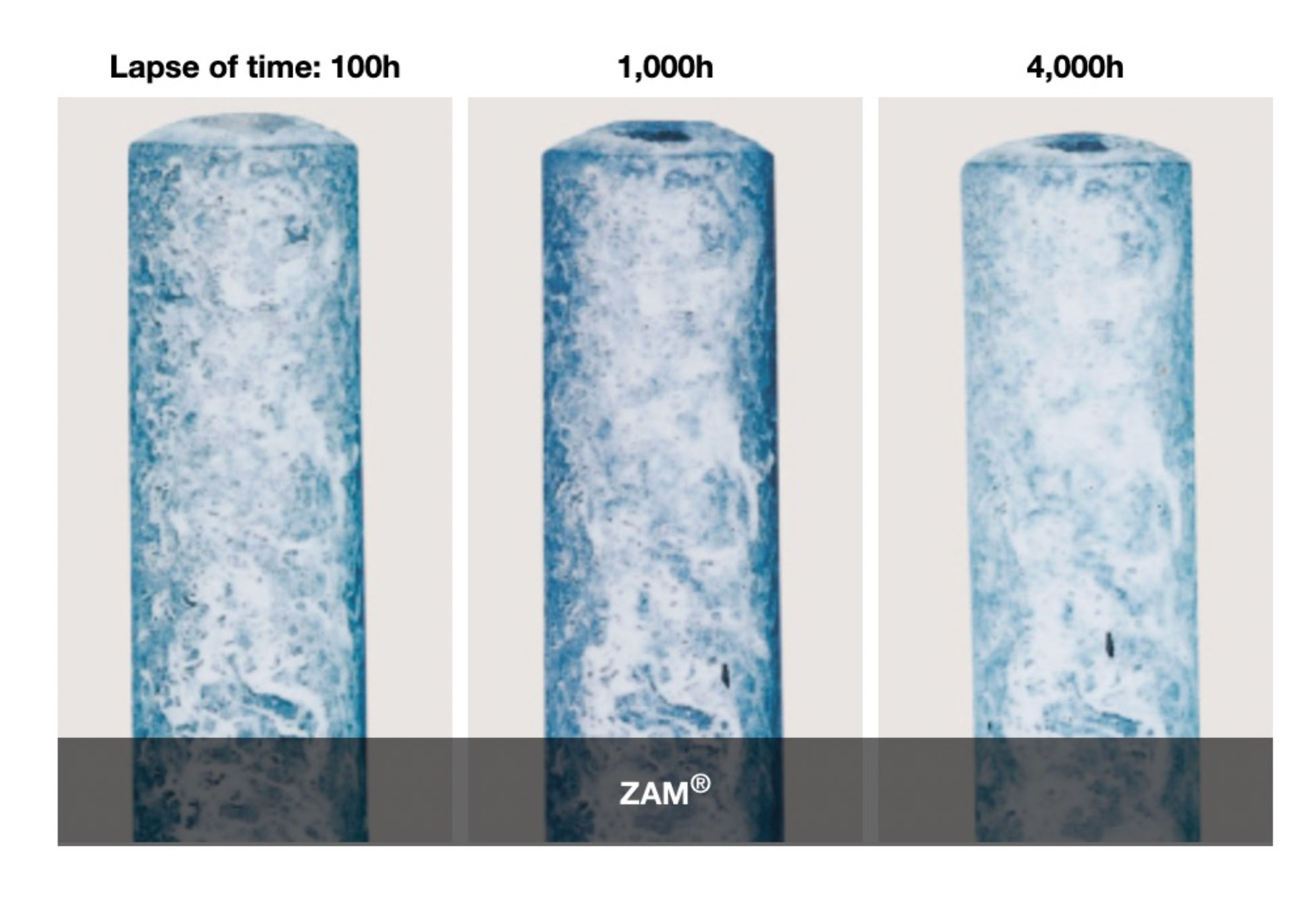

CHIKOUSA ZAM Tough

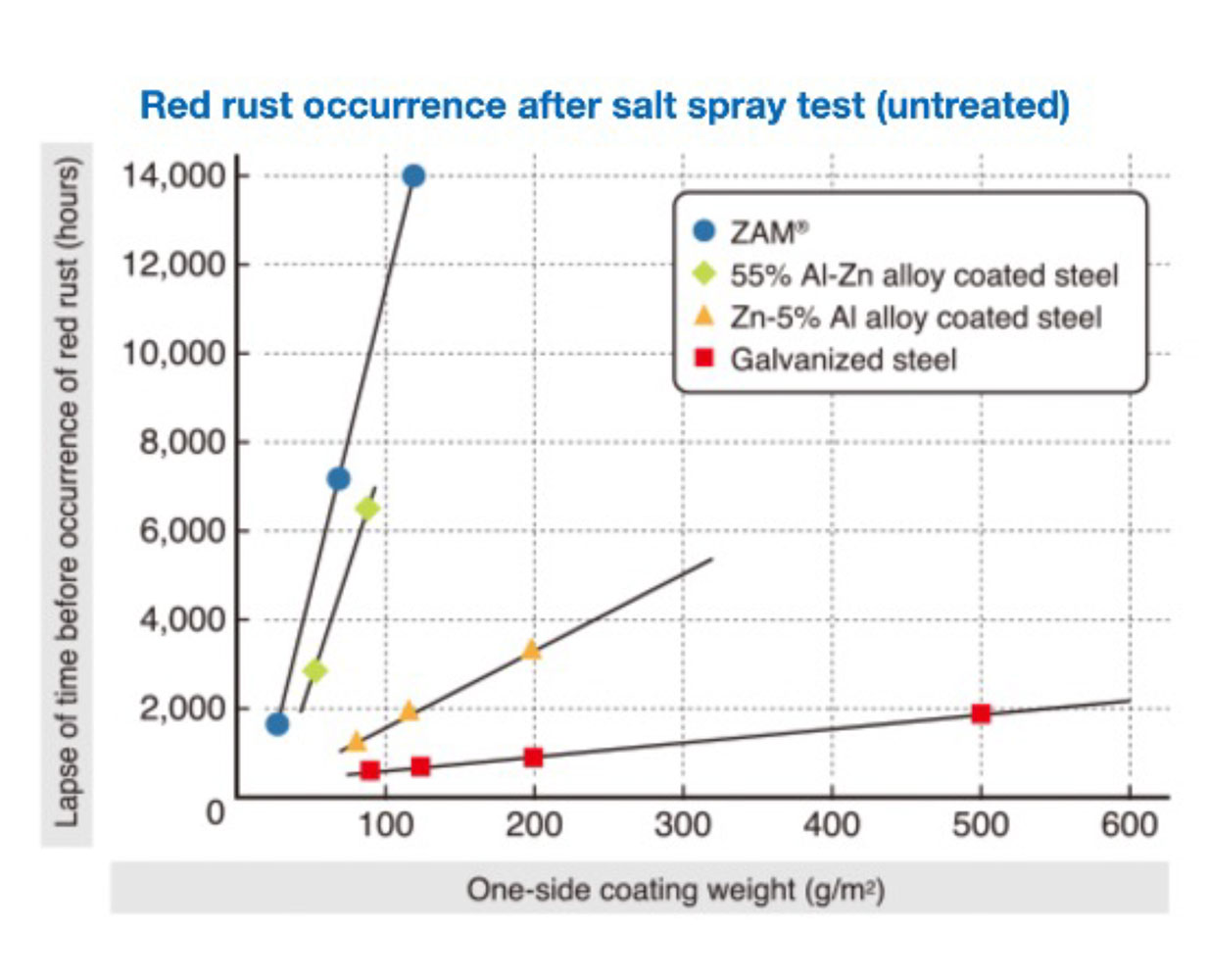

Corrosion Resistance On Flat Parts

ZAM has better resistance to red rust than galvanized!

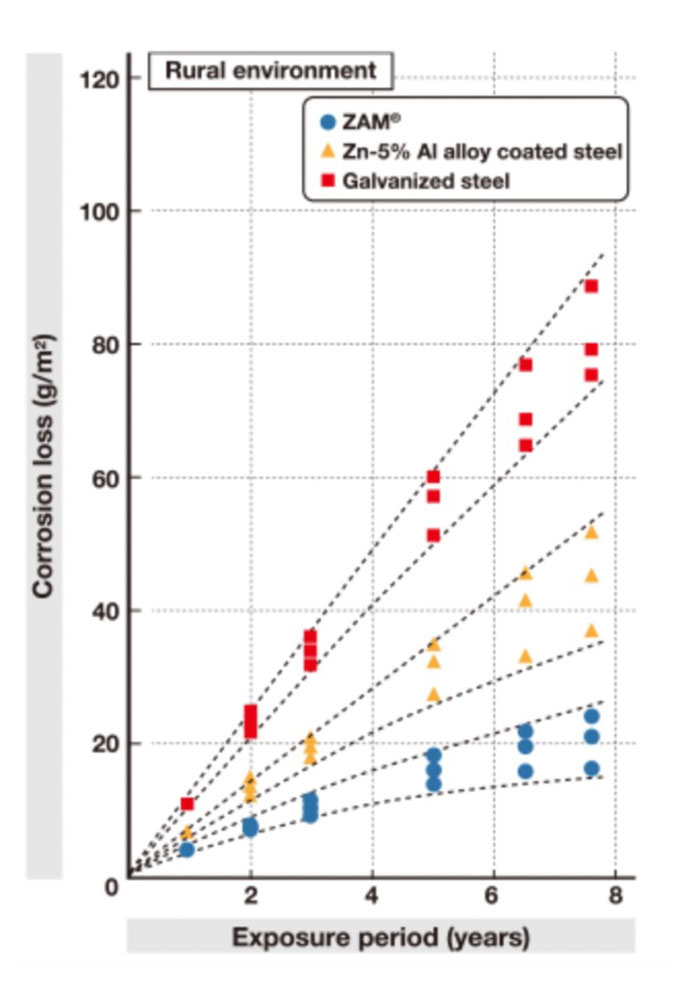

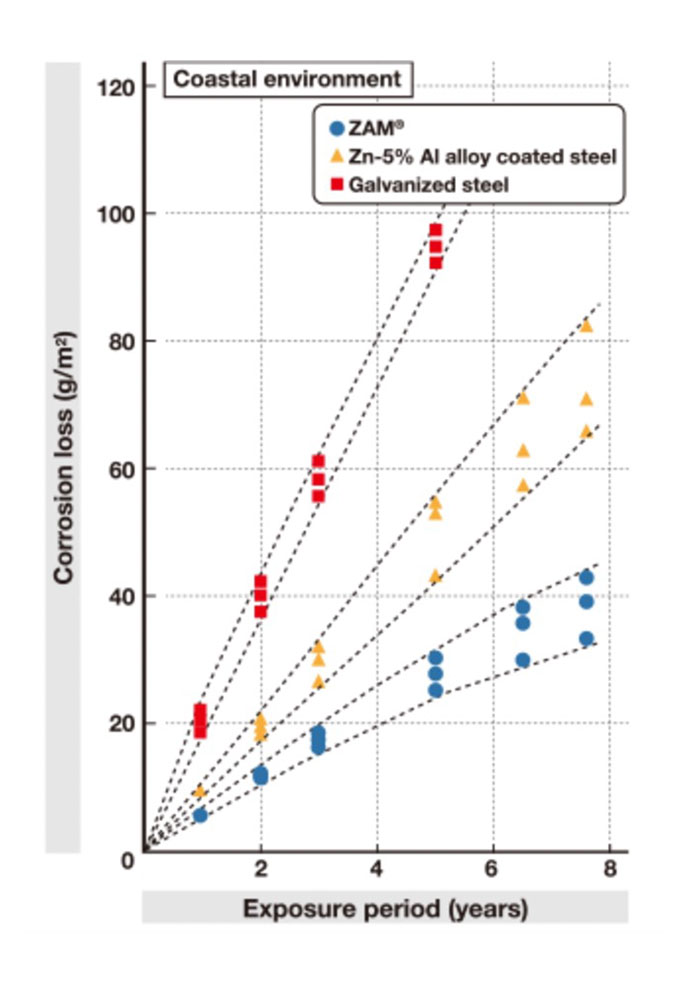

Outdoor Exposure Test Results

Corrosion Loss of Coating Layers After Outdoor Exposure Testing

ZAM show approximately four times higher corrosion resistance than galvanized

(according to the results of 8 years of exposure test)

Rural Environment

Coastal Environment

Appearances of 1t bent section after salt spray test

(1t, 180 bending, thickness: 3.2mm, 120/120 g/m, untreated)